Introduction:

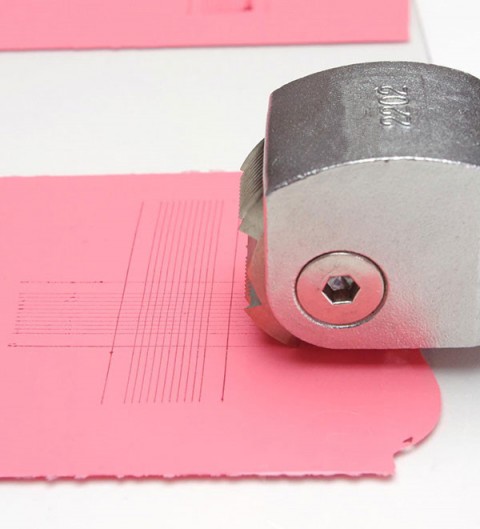

JR 2202 Cross Hatch Cutter is designed and manufactured according to ISO2409-1992, GB/T9286-98, BS 3900 E6 and ASTM D3359 standards.

Technical Specification:

| Cutting Head No. | Gap(mm) | Blades | Cutters Edges | Coating Thickness(µm) |

| JR 2202/1 | 1 | 6 | 8 | 0~60 |

| JR 2202/2 | 1 | 11 | 8 | 0~60 |

| JR 2202/3 | 1.5 | 6 | 8 | 0~60 |

| JR 2202/4 | 2 | 6 | 8 | 61~120 |

| JR 2202/6 | 3 | 6 | 8 | 121~250 |

Order Information :

| Standard Kit | Contain |

| JR 2202/1C | Cross Hatch Cutter + Carry Case + Hexagonal Screwdriver + Brush + Magnifier + Tape |

| JR 2202/2C | |

| JR 2202/3C | |

| JR 2202/4C | |

| JR 2202/6C | |

| Simple Kit | Contain |

| JR 2202/1S | Cross Hatch Cutter + Paper Box + Hexagonal Screwdriver |

| JR 2202/2S | |

| JR 2202/3S | |

| JR 2202/4S | |

| JR 2202/6S |

The evaluation criteria of the coating adhesion test:

Evaluation according to scale below:

| Description | Performance | Class(ASTM) | Class(ISO) |

| The edges of the cuts are completely smooth; none of the squares of the lattice is detached | 5B | 0 | |

| Detachment of small flakes of the coating at the intersections of cuts. A cross-cut area not significantly greater than 5% is affected |  |

4B | 1 |

| The coating has flaked along the edges and/or at the intersections of the cuts. A cut area significantly greater than 5%, but not significantly greater than 15% is affected |  |

3B | 2 |

| The coating has flaked along the edges of the cuts partly or wholly in large ribbons, and or it has flaked partly or wholly on different parts of the squares. A cross cut area significant greater than 35% is affected |  |

2B | 3 |

| The coating has flaked along the edges of the cuts in large ribbons and/or same square have detached parity or wholly. A cross-cut area significantly greater than 35%, but not significantly greater than 60% is affected |  |

1B | 4 |

| Any degree of flaking that cannot even be classified | 0B | 5 |